Waterproofing your commercial project is of the utmost importance. Without it, water infiltration can lead to significant damage with costly repairs and delays. EPRO’s methods of waterproofing, including underslab and blindside waterproofing, can save your building from foundation damage, mold, mildew and excessive humidity, prevent health hazards and reduce energy costs.

EPRO believes firmly in its products. With our nearly 30-year track record of excellence, we want you to be comfortable moving forward with a waterproofing company that you can trust. One such project that showcases valuable EPRO solutions is the Water’s Edge Complex project in Playa Vista, CA.

The Playa Vista area is a community that unites tech companies and professional sports teams, while simultaneously housing thousands of residents. It used to house the infamous Hughes’ Aircraft Company, and is even where the legendary Spruce Goose was manufactured.

The Water’s Edge office building is located within Playa Vista on wetlands and what used to be industrial manufacturing land, this means the site has extremely shallow groundwater, naturally occurring methane gas, and residual contamination for Hughes Aircraft Manufacturing. These conditions made the project incredibly challenging to build and required vigilance in protecting below-grade space. SPR:a was the architecture firm in charge of this six-story project.

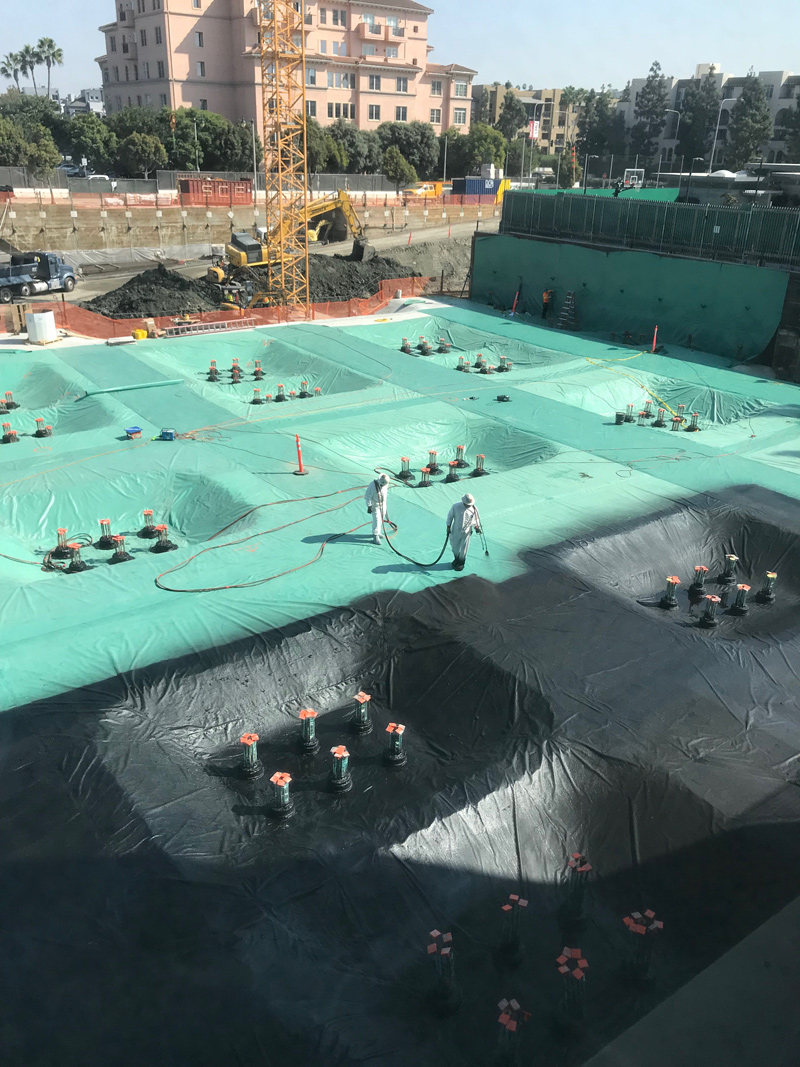

Phase Three of the Water’s Edge project, called WE3, was one of the final developments in the Playa Vista area. Only a mile away from the Pacific Ocean, the project was situated two levels below-grade, into the water table and supported by a pile foundation.

Due to the presence of methane gas and groundwater, which was contaminated with chlorinated solvents, it was determined that the below-grade waterproofing system needed to do much more than just keep water out of the structure.

With this new problem, the team had to go down two levels below-grade to provide a proper substrate for the waterproofing. Even at this depth, water still came in from different locations across the site.

It was clear that EPRO’s triple-redundant system was the ideal solution to simultaneously combat the high water table, methane gas and chlorinated-solvent-impacted groundwater.

“With the EPRO system you don’t need pre-manufactured elements to make conditions work. You have a certain flexibility with the system, but really, the best part about working with EPRO was being able to make the waterproofing system in tricky conditions,” said Josh Osorio, Assistant Project Manager of McCarthy Building Companies, Inc.

“There were a multitude of things at the site that made it complicated, from the logistics of moving the soil to the fact we had to employ the French drain system and pump out water at seven or eight separate locations at the perimeter and at the bottom,” continued Osorio.

Things only got more challenging when it was realized that the foundation was secured in place by auger cast piles.

“There were around 1,000 piles on the site that we had to waterproof and detail around, and the water was still coming up between the concrete and the rebar,” Osorio says. “In some places, we had so much water coming through some piles that we had to apply an additional waterproofing treatment just to stop the water pressure and subsequently apply EPRO.”

EPRO E.Protect+ was selected for the site, with EPRO and the architectural team configuring 91,000 square feet of E.Protect+ Underslab and 30,000 square feet of E.Protect+ Shoring.

The benefits of the E.Protect+ system made it the ideal choice for the project. Why?

EPRO’s E.Protect+ Underslab Protection system is ideal for structures with hydrostatic conditions and sites with potential hydrostatic conditions that may also contain the threat of methane gas or contaminant vapor intrusion. They are designed for structures with all foundation types.

EPRO’s E.Protect+ Shoring system provides blindside vertical protection against nuisance water, perched water or groundwater. It is also used to protect against the lateral migration of various contaminated vapors and methane gas.

E.Protect+ Underslab and Shoring systems are the first systems ever developed to combine in one system what others might utilize as three completely independent systems. It is designed for those who require the highest level of performance.

Sealing to piles that will be subjected to hydrostatic conditions requires flawless execution and technique. EPRO utilized prefabricated boots to speed up installation and provide the extra protection and detailing needed around the piles. EPRO’s redundant field-installed composite systems blend together factory-made components with those fabricated in the field, allowing the systems to adapt to many different conditions.

The project team appreciated the peace of mind offered through the support of EPRO’s E.Assurance no-dollar-limit warranty. McCarthy Building Companies, Inc. selected EPRO E.Assurance Certified Contractor Courtney Waterproofing to do the install.

“It was our goal to help Courtney so the installation ran very smoothly, without a hitch – and this was of particular importance in this high water table environment,” says Brian Miraki, Specified Products, Inc. “The job went well because we all planned well, and during the design process, we developed key details with the project team to address the most challenging and critical areas. Then at the preconstruction meeting, we worked through the project with the other trades because we wanted a smooth installation with zero surprises.”

Throughout the project, the EPRO team visited the site on a regular basis to supervise application and installation, and also to assist the construction and design team in solving any issues that arose during the project. EPRO’s due diligence ensured that there were no major delays. Ultimately, the overall speed and ease of installation were integral to the project’s success.

If you want to learn more about how EPRO’s systems can protect your next project, contact us for your no-obligation EPRO assessment.