Hot fluid-applied rubberized asphalt waterproofing is a monolithic, seamless, and fully adhered membrane system.

What Is Hot Fluid-Applied Rubberized Asphalt Waterproofing?

Hot rubberized waterproofing systems are fluid-applied membranes that consist of a blend of asphalt and modified rubber polymers containing mineral stabilizers. These waterproofing systems create monolithic membranes that can cover a large surface area.

Hot rubberized membranes, as the name suggests, are applied while extremely hot. The material is typically heated in jacketed kettles that are gas-fired and delivered in buckets by pump or in the hands of a professional.

It is extremely important that the temperature of the product in the kettle is maintained within specified ranges. For most manufacturers, the acceptable range is between 350 and 400 degrees Fahrenheit. However, excessive amounts of heat can cause the product to disintegrate. It will subsequently fail to cure properly once installed.

Applications

Hot fluid-applied asphalt waterproofing can be applied on horizontal or vertical structures.

It can be appropriate for use on the following:

- Below-grade waterproofing

- Tunnels

- Parking Decks

- Balcony Decks

- Roofs

- Vegetative Roofs

- Podium Decks

- Planters

- Split-slab Applications

- Vertical Foundation Walls

- Plaza Decks

Benefits

Three key attributes of hot fluid-applied asphalt waterproofing are:

One: it eliminates seams, thus reducing potential issues with detailing transitions on systems such as roofs.

Two: it drastically reduces the risk of leaks.

Three: it can have aesthetically pleasing finishes.

Hot rubberized membranes were designed in order to provide effective waterproofing for large surface areas. They excel in conditions with intricate transitions and, when they are applied correctly, the benefits are outstanding.

Fluid-applied materials also provide particular advantages in vertical applications. They are easier to install than regular sheet membranes, and because they are liquid, they can fill naturally occurring imperfections, becoming a part of the existing substrate. However, extreme caution should be taken when applying hot rubberized asphalt to vertical surfaces.

Fluid-applied applications are often much less labor-intensive compared to installing pre-formed sheet membranes. It can save some projects up to 60% in labor costs. Less labor means less time, so construction schedule timelines can often be greatly reduced.

It’s important to note that hot fluid-applied products (vs. cold) require more material preparation time. Additionally, without safety precautions and professional installers, it can be deemed less safe to use than cold-applied products. But hot fluid-applied products can be advantageous in certain climate conditions and with certain substrates.

The benefits of hot fluid-applied products include:

- It is a fully functional membrane and waterproof within seconds of application

- It can withstand constant immersion in ponded water

- Has a water absorption rate of less than 1%

- Is resistant to a wide range of soils, microorganisms and chemicals

- Is corrosion-resistant

- Can be applied to “green concrete”

- Can withstand thermal cycling

HotDeck System

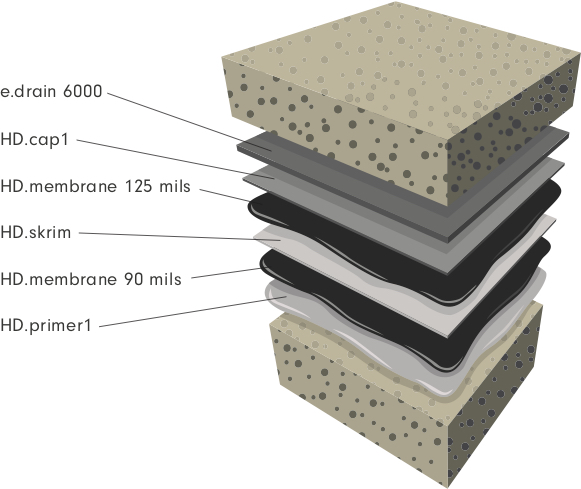

EPRO’s HotDeck Waterproofing Protection System allows building owners to single-source their below-grade and above-grade waterproofing. It features a 215 mil reinforced layer of HD.membrane, a hot fluid-applied rubberized asphalt with reinforcement. The system cures to form a seamless, fully-bonded, tough, thick yet highly flexible waterproofing membrane to offer you the best protection.

HotDeck is ideal for split-slab deck applications, as well as pedestal paver decks and vegetative decks, and the system consists of multiple layers.

The first layer is EPRO HD.membrane 90 mil, the second layer is EPRO HD.skrim reinforcement, the third layer is EPRO HD.membrane 125 mil, and the fourth layer is EPRO HD.cap1 or HD.cap2 — a premium polymer-modified fiberglass protection sheet.

An additional component is the EPRO e.drain 6000 — a lightweight, three dimensional, high-compressive strength polypropylene core that is bonded with non-woven geotextile fabric. All together, the components of HotDeck protect the rubberized HD.membrane from physical damage through the construction process, UV exposure and provide redundant layers of long-term waterproofing protection.

The benefits are immense. Three layers of waterproofing materials create a composite system - superior to using the individual materials alone. The reinforced hot fluid-applied rubberized membrane has no seams, and therefore no leakage. It is fully bonded because the system mechanically bonds to concrete.

EPRO’s products are industry-standard with proven technology that works. Don’t believe us? Take a look at our warranty. Combine HotDeck with EPRO’s below-grade systems for increased protection and have a single-source warranty for the entire structure.

Reach out to EPRO with any questions you might have or to collaborate on your next project.