Properly waterproofing your foundation will result in a dry and safe below-grade environment. Experts agree that there are certain foundation waterproofing best practices to ensure your below-grade waterproofing membrane is applied correctly, to ensure there is no water leakage and damage as a result of those leaks.

There are certain below-grade waterproofing products and techniques that will help you complete your project on time and within budget.

Remember, below-grade waterproofing is not one size fits all; each site presents its own unique challenges, and selecting the wrong product can produce poor results. We are here to help you make the best choice for each of your projects, as no two projects have the same requirements.

Redundant Layers of Protection

Redundant waterproofing systems achieve several goals: They protect against water infiltration on a basic level by utilizing complementary waterproofing technologies, help overcome the challenges presented by modern-day construction methodologies, and help ensure a healthy building environment by protecting occupants from contaminants that might be present on the site.

Redundancy within a waterproofing system is important because there is not a single “silver bullet” waterproofing product that can accommodate all site conditions and environments. Additionally, site conditions are becoming more challenging. Foundations are being built deeper and developers now like to utilize structural shotcrete due to its cost and time savings.

When a building is subjected to hydrostatic or perched water conditions, the requirement for perfectly installed waterproofing increases exponentially. Water is very patient, and the consistent and steady force it exerts on waterproofing system weaknesses will likely result in water migrating into the structure.

To help combat these challenges, redundant waterproofing systems are more effective as redundant options combine several different types of waterproofing materials to leverage the positive attributes of each and to eliminate negative attributes, forming one collective system that is resistant to damage and contains fewer overall seams. These redundant systems can accommodate a wide variety of different site conditions and even be tailored to resist contamination that is present on so many sites that are being redeveloped. \

Check Your Warranties

A waterproofing warranty is a legally binding agreement between a manufacturer and a building owner that guarantees some or all of its work will be free of defects for a specific length of time. Different suppliers will have vastly different warranty terms for what appears on the face to be the same type of warranty so evaluating the specific warranty language before selecting a product manufacturer is very important.

There are 3 main types of warranties: No Dollar Limit (NDL), Labor and Material, and Material Warranty.

The most common type of warranty is a Material Warranty. It is the most limited type of warranty as it only covers the cost of replacing defective material. If the materials are proven to be defective, this warranty will recover the cost of the failed product or repair the faulty component. EPRO provides this warranty free of charge. This type of warranty provides a building owner with the lowest level of protection in the event of water ingress.

Labor and Material warranties, also known as system or watertight warranties, are designed to make one party responsible if the building envelope is not performing as specified in the agreement. When an L&M warranty is issued, the workmanship of the installer and the performance of the materials are covered by the manufacturer. Check out EPRO’s L&M warranty language here.

An NDL warranty is like a labor and material warranty but provides building owners peace of mind knowing that any costs associated with repairing a defective waterproofing system will be covered by the manufacturer. Unlike limited warranties, there is no maximum coverage amount. Whether it is $5,000 or $500,000, an NDL warranty guarantees that the manufacturer will pay for it. EPRO provides an E.Assurance NDL warranty, and you can learn about it here.

Invest in a Quality Dewatering System

A crucial component to successful waterproofing installation is making sure the site remains free from groundwater while the waterproofing system is being installed. Dewatering systems can temporarily relieve the site from groundwater during the construction process, or they can be utilized for the lifetime of the structure.

Not investing in a quality system may prevent the waterproofing system from being installed correctly due to excessive moisture. One way to make certain that the waterproofing assembly is protected and water is channeled to the proper discharge location is by incorporating a drainboard.

The main purpose of a drainboard is to provide a gap so that water running towards the foundation hits the drain and flows down to the footing drains, effectively acting as a pressure relief valve.

Also, the drainboard provides extra protection to the waterproofing membrane against the grain rock or whatever material is being used as a backfill material.

Properly Waterproofing the Entire Building Envelope

A properly installed below-grade waterproofing system can perform as designed and be free of any leaks, yet water can still be found in the building's basement. How is that even possible?

Water flows downhill and follows the path of least resistance. If the above-grade areas are not properly sealed, water can circumvent the entire below-grade waterproofing system. One possible solution to prevent this is to also select a robust above grade horizontal waterproofing system.

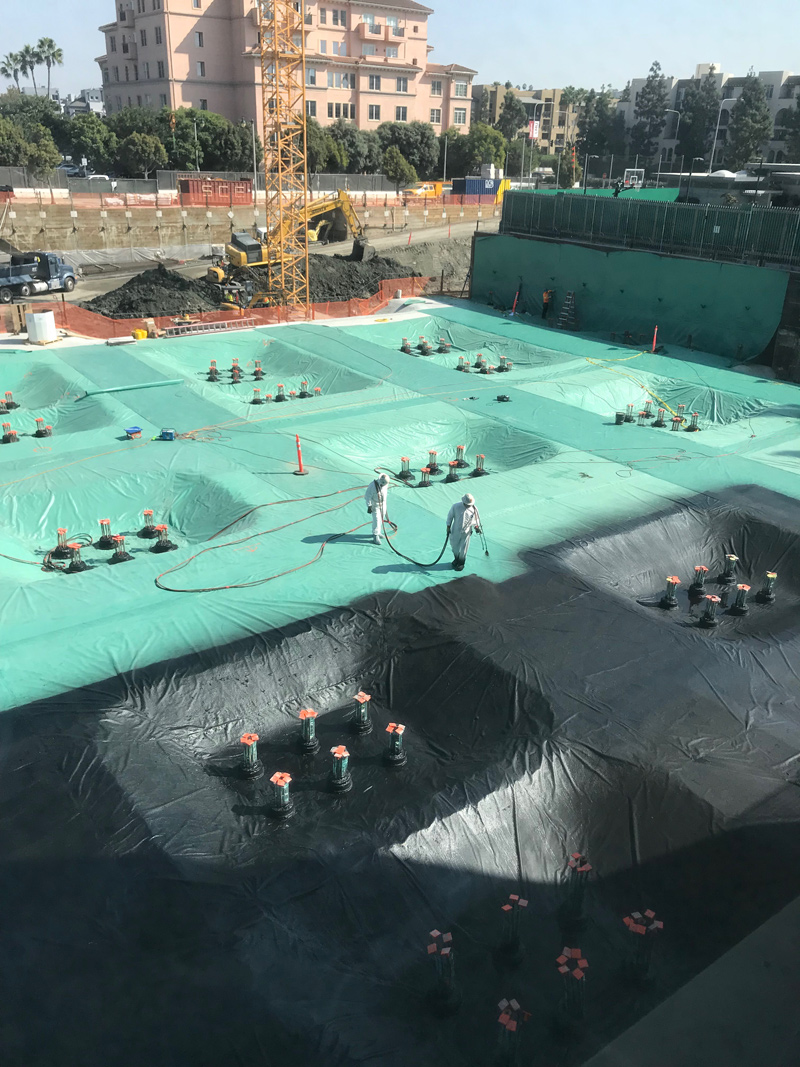

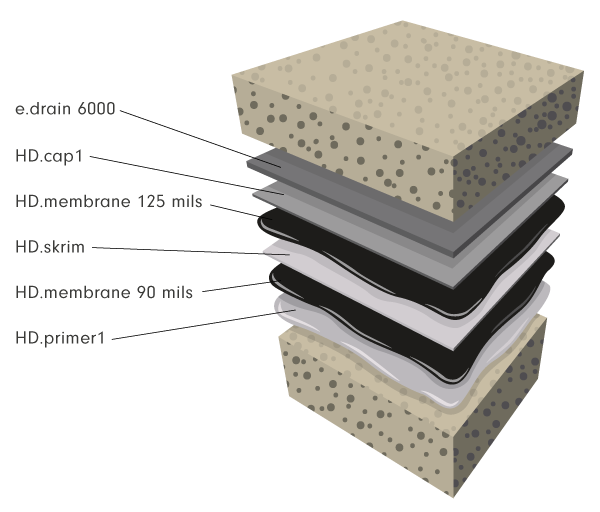

EPRO offers HotDeck, a waterproofing protection system that features a 215 mil reinforced layer of HD.membrane, which is a hot fluid-applied rubberized asphalt with reinforcement. Once it is applied, it cures to form a seamless, fully-bonded, thick, tough, yet highly flexible, waterproofing membrane.

Together, components of HotDeck protect the rubberized HD.membrane from any physical damage that happens throughout the construction process, UV and beyond, as well as provide redundant layers of longer-term waterproofing protection.

Achieve Waterproofing Best Practices With EPRO

When waterproofing foundations, there are countless products and techniques to use — but not all of them suit your project’s best interests. If you are feeling overwhelmed, you should reach out to an expert in the industry who’ll have a team with vast experience and a willingness to share their knowledge. A team like EPRO. We can help you pick the right product combination to ensure your project is a success from day one and years afterward.

Reach out to EPRO for any questions you might have or to talk about a specific project’s needs by clicking here.